Flanged Immersion Heaters

Flanged Immersion Heaters

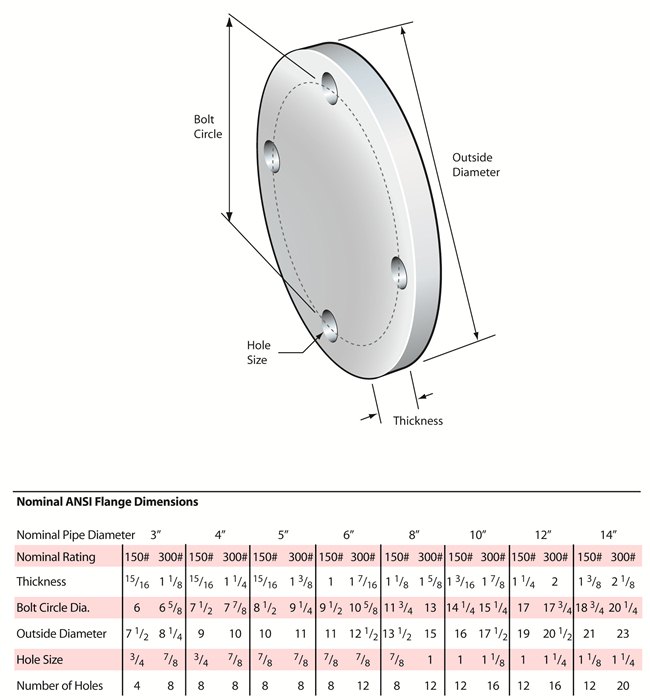

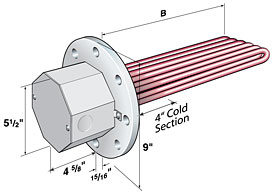

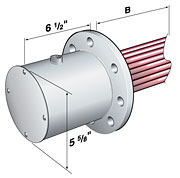

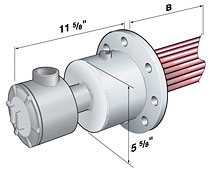

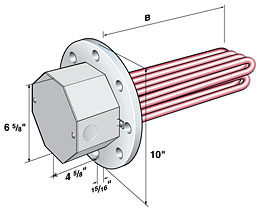

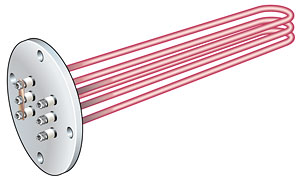

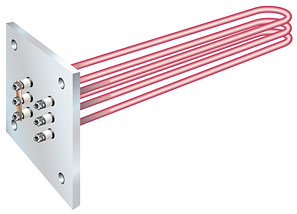

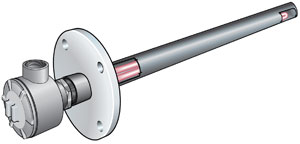

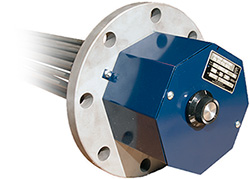

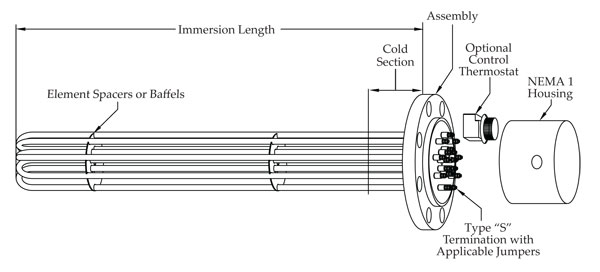

ProTherm flange heaters are high capacity electric heating elements made for tanks and/or pressurized vessels. They consist of multiple tubular heaters formed into a hairpin shape and brazed to ANSI flanges. The heating elements can be made of copper, steel, stainless steel or Incoloy sheath. Standard flanges are composed of carbon steel rated for 150 or 300 Lbs. Other flange materials and shapes are available. Various types of electrical protection housing, built in thermostats, thermocouple options and high limit switches can be incorporated.

Flange Heater Material Options

In order to meet the heating requirements of your application, and have a safe operation in the environment within which the heater operates, several factors should be taken into consideration in the design of your heating element. The following are a number of criteria that should be considered:

- The pressure rating and the material of a flange.

- The sheath material of the tubular elements. The table below provides recommended tubular sheathe and flange material for different mediums.

- Operating temperature and a watt density of tubular elements that are adequate to the material heated. The table below provides maximum operating temperatures and watt densities that are recommended for heating various materials.

- Design watt density, flow velocity, outlet temperature are factors that contribute to the temperature level that tubular elements will attain.

- Safety issues considering the environment within which the immersion heater will operate.

- Utilization of adequate temperature controlling devices, temperature and pressure high limit switches, low liquid level and flow controllers and other control/safety devices that will control the heating process and protect the heater from excessive heat.

- The classification of the electrical terminal box required (NEMA1, NEMA4, NEMA7 and NEMA12).

- The level of the contamination that the immersion heater will be exposed to

- Safety and electrical code consideration

- The possible requirement of baffles that force a gas or a liquid to circulate around heating elements when flanged immersion heaters are used inside circulation tanks.

The table below shows the maximum temperatures that different sheath materials could be subjected to:

| Sheath Material | Maximum Temperature |

| Copper | 360° F (180° C) |

| Stainless Steel | 1200° F (650° C) |

| Steel | 750° F (400° C) |

| Incoloy | 1500° F (815° C) |

For more information in selecting flange heaters please contact us.

| Application | Sheath Material | Flange | Typical Watt Density |

| Clean water | Copper | Steel | 45 |

| Process water/Weak solution | Stainless Steel | Stainless Steel | 25-55 |

| Oil light | Steel | Steel | 20-25 |

| Oil medium | Steel | Steel | 12-15 |

| Corrosive solutions | Incoloy | Stainless Steel | 20-25 |

| Vegetable oil | Stainless Steel | Stainless Steel | 25-30 |

| Asphalt, tar, wax | Steel | Steel | 6 |

| Air | Incoloy | Steel | 23 |

Optional Flange Heater Features

- NEMA 4 Terminal Box

- NEMA 7 Terminal Box

- 300 lb. Rated Flange

- Stainless Steel Flange

- Terminal Box Options (stilted, vented, stainless steel)

- Built In Thermocouple

- Baffles

- Various Temperature Thermostats

- High Limit Controllers

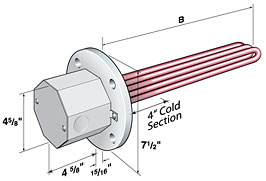

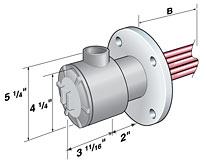

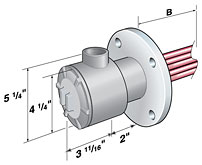

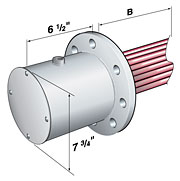

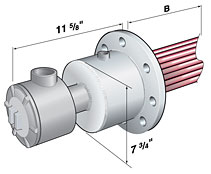

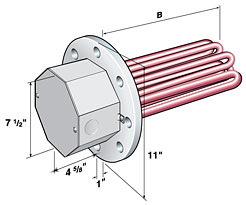

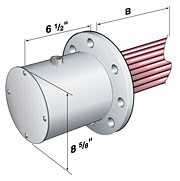

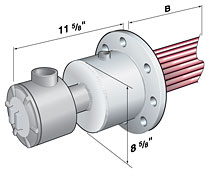

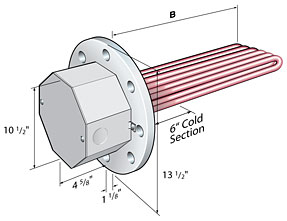

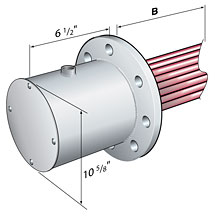

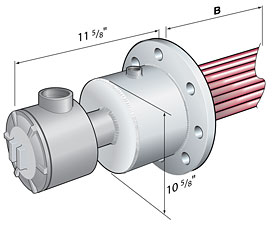

Flange Heater Terminal Housing Options

| 3”-150 # ANSI Flanged Heaters | ||

|

|

|

|

| 4”-150 # ANSI Flanged Heaters | ||

|

|

|

|

| 5”-150 # ANSI Flanged Heaters | ||

|

|

|

|

| 6”-150 # ANSI Flanged Heaters | ||

|

|

|

|

| 8”-150 # ANSI Flanged Heaters | ||

|

|

|

|

| Non-Standard Flange Options / Designs | ||

|

|

|

|